Every day, we see and use multiple products as we go through life. The soft drink you buy on your way home, the refrigerator you use to keep your drinks cold, and the bed you sleep in after a busy day. All these products are manufactured, but by what process? Can we figure it out? Well, yes, we might be able to if we clearly understand the differences between various manufacturing processes. But here, we will focus on the two main types of manufacturing processes used to produce products.

Discrete manufacturing vs Process manufacturing

Discrete manufacturing is a reversible process, while process is irreversible.

Manufacturing method in which several distinct components combine to make a single product (Unit) that can easily be reverted or recycled again into original components is known as Discrete manufacturing.

Products like toys and tools can be returned to their original state if we see any defect in the lot. Also, you can collect broken toys and restore them without compromising their quality.

While in process manufacturing, various components (Raw materials) move through either chemical, physical, or biological processes to turn into a final/end product.

Like a lipstick, an eye cream, or a toothpaste. All these products are made by combining some components in a series of continuous or sequential processes, and these components cannot be reverted to their original state once made.

Discrete manufacturing

The manufacturing process in which companies produce countable items by assembling different distinct components to create one final product.

- In discrete manufacturing, the product you manufacture is often identified, counted, and can be easily disassembled for recycling or reuse.

- In DM, each product is assembled from a specific set of components using a bill of materials (BOM), and customization is often possible.

- You can convert the finished product back into individual components.

- Items made by DM are usually sold as a single unit, like one piece of furniture made with wood that you can discard, and then recycled using the same components without altering their quality.

Here is the list of all the prominent features of discrete manufacturing;

| Feature | Description |

| Production Type | Item-based, individual or separate units |

| Product Nature | Tangible, countable items like cars, electronics, furniture |

| Bill of Materials (BOM) | Defined BOM for each finished product |

| Assembly Process | Assembled from components or sub-assemblies |

| Customization | Often allows for high variability or customer-specific orders |

| Production Flow | Can be linear or flexible; often involves multiple stages |

| Changeover Time | Medium to high, especially with varied product lines |

| Inventory Type | Maintains inventory for raw materials, WIP (Work In Progress), and finished goods |

| Typical Industries | Automotive, aerospace, electronics, home appliances, machinery |

| Production Volume | Low to medium volume; can also be high for standardized goods |

| Order Tracking | Easy to track unit-by-unit (serial numbers, barcodes) |

| Examples of Products | Smartphones, bicycles, computers, cars, toys |

<script>(window.openVideoPlayers = window.openVideoPlayers || []).push({ target: document.currentScript, videoID: “1e4a8bddcefd7e0b3068ac6d25555290f986bdba” });</script><script async data-cfasync=”false” src=”https://www.open.video/video.js“></script>

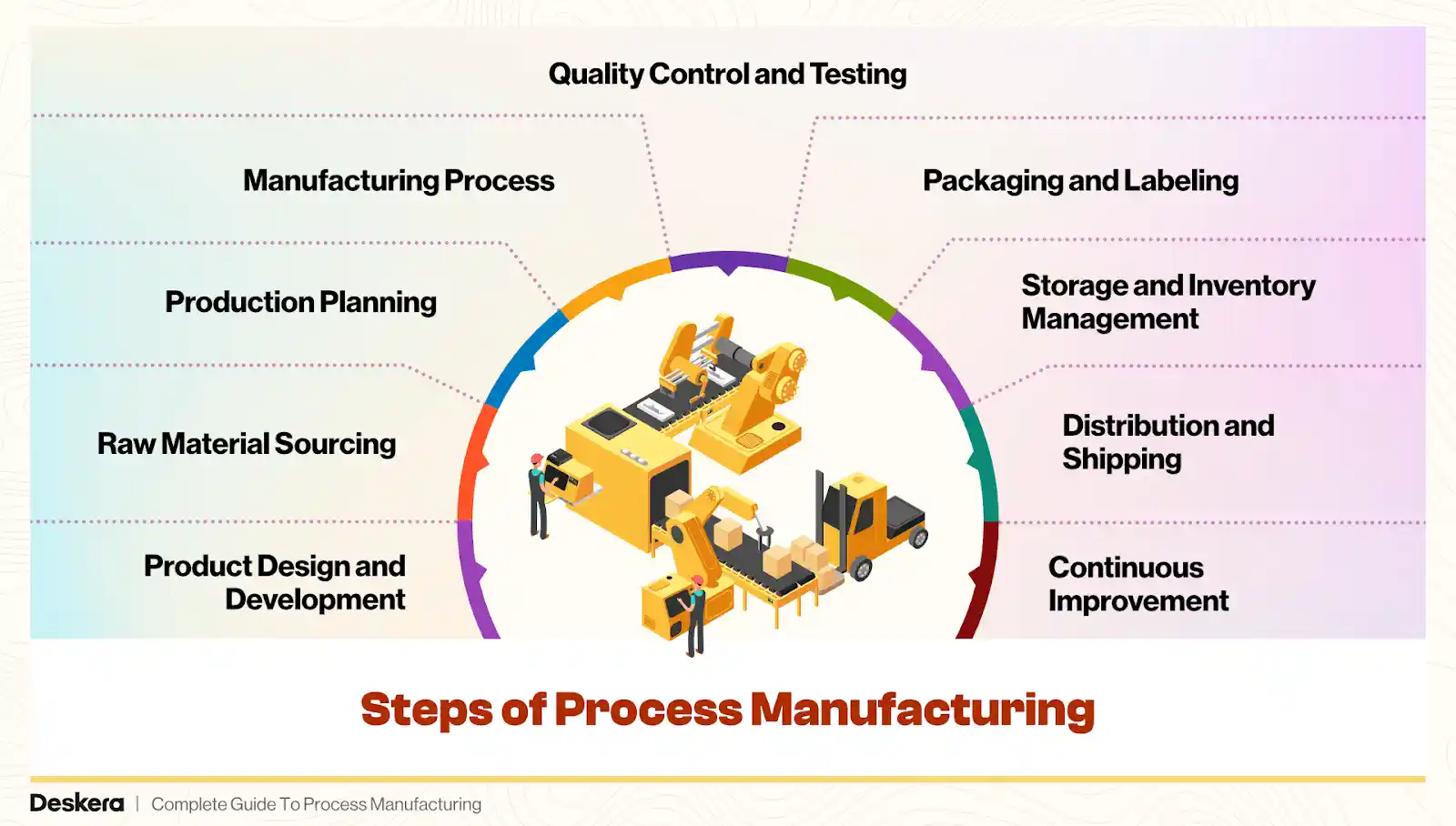

Process manufacturing

Unlike discrete manufacturing, process manufacturing is irreversible. In this, you combine separate components (raw material) using chemical, physical, or biological processes that cannot be converted back into the original state once the product is made. This approach is commonly use in industries like This approach is common in industries like food and beverage, pharmaceuticals, chemicals, and oil and gas.

- In PM, the finished good is non-countable and involves mixing and processing ingredients using certain formulas.

- In PM, once made, you cannot separate the material used to make the finished good back to the original state, like you cannot separate or reverse mineral oil and white petrolatum from an eye ointment once made.

- Unlike discrete the products made in PM are non-countable and involve continuous output (litres, tons). You can produce bulk products like large volumes of eye ointment, but you can still sell them as single units, just like in discrete manufacturing.

| Feature | Description |

| Production Type | Continuous or batch-based production |

| Product Nature | Bulk, non-discrete items, cannot be easily separated into distinct units |

| Bill of Materials (BOM) | Uses formulas or recipes instead of traditional BOM |

| Assembly Process | Blending, mixing, or chemical transformation of raw materials |

| Customization | Limited customization; mostly standardized products |

| Production Flow | Linear and continuous, often nonstop |

| Changeover Time | High; difficult and time-consuming due to cleaning and setup between batches |

| Inventory Type | Tracks raw materials, bulk inventory, and storage tanks |

| Typical Industries | Chemicals, food & beverage, pharmaceuticals, oil & gas, paint |

| Production Volume | High volume, large-scale production |

| Order Tracking | Tracked by batch/lot number, not individual units |

| Examples of Products | Soft drinks, paint, gasoline, flour, detergent, cement |

Are all products made with either of the two approaches or not?

Well, we cannot categorize any product into either of the two mentioned approaches completely. Why? Because as the product is being made, it moves through different stages, and in each stage, the process used can be discrete or process-based, depending on the production stage, company setup, and complexity. Let me explain more clearly.

Take a chocolate bar, for example. The chocolate is made using the process manufacturing approach, like non-countable and in tons. But once made, it is packaged and sold as a single discrete unit, as in discrete manufacturing.

Now consider the same process for toothpaste, juice, personal care products, and others. They all fall into the gray area where we cannot categorize each product or category as one or the other, because both processes are used at different stages of manufacturing.

How Seebiz can help

In both manufacturing approaches, to ensure a smooth and error-free operation, you must manage your raw materials, timelines, and production processes to prevent any delays, shortages, or human errors. Therefore, you can use Seebiz inventory management software, specifically designed with manufacturers‘ and wholesalers’ needs in mind. You can set reorder points, quantities, make one-click bills, and much more simply by using a single tool.

Start managing your manufacturing process to prevent any possible errors.