Before we jump into the solution for “the best way to grow a small manufacturing business,” we need to focus on the major problems holding it.

With President Trump focusing on bringing manufacturing back to the US, other problems might wait for the industry’s return: the skill gap, poor employee retention, less tech adoption, and the high cost of domestic labour.

Before focusing on growing the business, we should consider how small manufacturing businesses can resolve the major issues that directly impact their growth.

Filling the skill gap

Current scenario of skills gap:

Skills gap, an aging workforce, negative perceptions, and the mounting cost of hiring domestic labour – that’s what the US manufacturing industry has to say about its sector, Business Insider reported recently.

Most US manufacturing firms are small:

- Total manufacturing firms in 2022: 239,265

- Small firms (under 500 employees): 4,177

- 75% of these have fewer than 20 employees

- 93.1% have fewer than 100 employees

Most employment comes from the first category (with fewer than 500 employees). The employment rate in the US manufacturing industry has been dwindling since 2022. The factors might be many.

According to the Manufacturing Institute, more than 65% of companies said recruiting and retaining workers is their top business challenge. Another closely related issue is that most of the manufacturing labour is retiring and aging, leading to an average of 500,000 jobs opening each month for several years.

Impact of Aging Workforce and Tech Stack Changes:

Companies are facing a large skill gap, with old employees familiar with outdated tech stacks and techniques. This is quite concerning, as companies returning to the US cause more openings but fewer positions filled. According to the Manufacturing Institute and Deloitte, between 2024 and 2033, the manufacturing industry will need 3.8 million net new employees. That needs serious consideration.

Education and Technical Expertise Gap:

Another closely related factor is the education gap. Only 40% of manufacturing jobs involve directly making products. The other 60% require technical expertise in robotics, electrical systems, and digital controls. That means people without college degrees won’t find appropriate roles in the industry.

That’s the same issue raised by Sameeksha Desai, an Associate Professor at Indiana University and director of the Manufacturing Policy Initiative. Skills like cybersecurity, digital skills, and data management are also workforce concerns.

But is America working on training its workforce yet?

Only 0.3% of American workers have apprenticeship training, compared to 3.6% in Switzerland, 12x higher. That puts us behind when it comes to getting skilled labour.

Recommended Solutions to Fill the Gap:

Now, the solution lies in companies either investing in employee skills development or considering hiring employees based mainly on skills rather than seeking a compulsory four-year degree.

The shift will take time to adjust, but with rising concerns, there should be direct investment to fill the skill gap as early as possible.

By considering workforce challenges, businesses can effectively fill the open positions in the manufacturing sector.

1- Higher domestic labor cost

With the recent trade war bringing manufacturing back to the US, the ground is not yet ideal for manufacturers operating in other countries to play it safe and economically in the US.

Domestic labor costs in America are much higher than in many other countries.

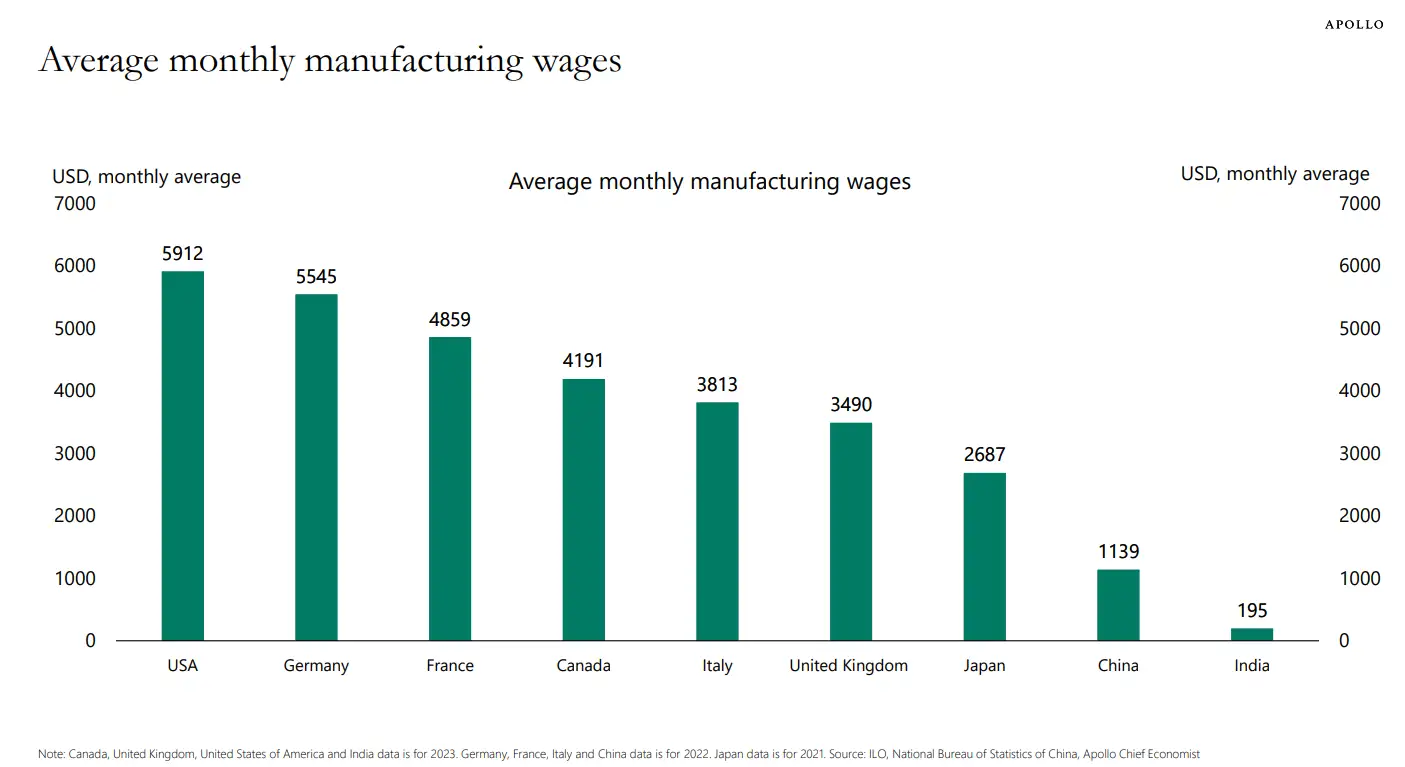

For example, manufacturing wages in China are now about 20% of those in the US, and in India, they are around 3% of US wages. In Mexico, wages range from $2 to $6 per hour; in the US, they can exceed $20 per hour.

A survey conducted by Apollo in 2024 also highlighted the wage difference between domestic labor in different countries, with the US topping the chart with the highest monthly manufacturing wage.

Therefore, manufacturing the same product that companies were manufacturing in other countries in the USA might cost them 4x—5x as much.

That may disrupt their normal manufacturing cycle.

2- Poor employee retention

The same factors that make recruitment difficult also hinder retention. Many manufacturing jobs that don’t require a four-year degree are considered repetitive, which causes a perception of a lack of advancement in employees.

Similarly, with technological advancement, companies seek employees with broader skill sets. Still, the older workforce, lack of training, and getting too comfortable with the typical manufacturing framework slow down manufacturing industries, ultimately causing both employees and the company to feel overwhelmed.

3- Less technological adoption

Tech is on its rise. In every major sector, we have been seeing revolutions. Companies are working 2x faster with new tools and technologies on tasks that are repetitive and too boring for human resources. That created the need for humans in the other side of manufacturing, which is more tech-driven, like robotics, electrical systems, digital controls, cybersecurity, etc.

However, with fewer apprenticeship programs and less investment in skill development, there is a gap between what manufacturing aspires to be and its current position.

Manufacturing needs young minds with technological creativity to scale small manufacturing businesses and create more opportunities for others.

The best way to grow a small manufacturing business

We identified the major problems that small manufacturing businesses are facing. Now we come to the part where we are going to discuss how we can still scale,

Start small

If you haven’t yet invested in technology. Start using it.

Invest in smart technology and ERP (enterprise resource planning) software. This software system helps you manage everything – inventory, orders, production, and finances – in one place. So if you manually do all of this, you are hurting your finances and time.

A small investment can make big returns.

Invest in employee skill development

If your best employee lacks a specific skill set that can double his performance, then instead of hiring a new employee with that skill set, you can simply invest in the skill development of your current employee. This approach will cost you less and generate more revenue than hiring new employees. According to an HR Magazine report, companies investing more than $1500 per employee every year show on average 24% higher profit margins than companies with a lower training budget.

Build strong supplier relationships

For a manufacturing business to operate smoothly, it must have a strong supplier relationship. Supply chain issues have been a big headache for manufacturers lately. A single delay can stop your operation if you rely on just one or two suppliers.

How to improve:

- Build relationships with multiple suppliers.

- Consider local suppliers to reduce shipping times.

- Negotiate clear contracts and backup plans.

Check in with your suppliers regularly. Good communication can help you spot problems early and find solutions before they become crises.

Use Lean Manufacturing

Lean manufacturing isn’t just for big companies. It’s about finding and cutting out waste, whether that’s time, materials, or money.

Simple steps to get started:

- Organize your workspace (the “5S” method: Sort, Set in order, Shine, Standardize, Sustain).

- Map out your production process and look for bottlenecks.

- Ask your team for ideas to save time or materials.

Start small. Pick one area to improve each month and build from there.

Conclusion:

There are multiple ways to grow your small manufacturing business, but focusing on the root causes will greatly help you in the long run. As a whole, US manufacturing is experiencing a shift once again after the COVID-19 outbreak, and all we have to do is get ready to face it.