If you’re in the manufacturing or wholesale space, you’ve probably heard the term repetitive manufacturing thrown around. But what exactly does it mean, and how do you know if it’s the right model for your business?

In this guide, we’ll break it down in simple terms, compare it with discrete manufacturing, and show you how wholesalers and manufacturers are using it to cut costs, speed up delivery, and scale with fewer headaches.

What is repetitive manufacturing?

Repetitive manufacturing (RM) is a factory process designed for rapid, continuous production flow, where the same product (or a very similar one) is made repeatedly over an extended period. Same inputs, same process, same output – day in, day out.

This model is ideal for companies that deal with high-volume, low-variation products. It primarily uses assembly and production lines, specializing in making the same or very similar products over long periods. This method is often referred to as “rate-based manufacturing,” where the objective is a steady stream of products, frequently a mix of similar items, rather than individual batches.

How repetitive manufacturing works

RM is ideal for mass-producing items with only minor design variations, especially when there’s a consistent, high-volume market demand. This method is commonly use for the production of durable goods, cars, electronics, and even packaged foods like canned goods or snacks.

This type of production operates on a strict schedule, with daily, weekly, or monthly targets, to make sure the set production rate and consistent quality.

One of the key characteristics of RM is its ability to minimize setup times between products, as the production line is dedicated to a family of similar items. This approach naturally leads to shorter manufacturing lead times.

This approach practically reshaped the consumer markets by making accessible and affordable products for consumers. And the companies that are using this method for mass producing goods are significantly saving a lot of money, which allows them to offer their product at lower prices.

The first product of repetitive manufacturing

A lot of us have already been aware of the Model T introduced by Henry Ford in 1908. It was the first mass-produced car that became increasingly demanding due to its affordability.

This approach was first developed for market expansion and affordability because what’s more strategic than introducing a market-competitive product at a dreamy price that profoundly impacts societal consumption patterns?

Key characteristics of repetitive manufacturing

1- Automation

As we have discussed how in repetitive manufacturing, we produce large quantities of the same product to speed up production, reduce waste, pollution, and of course make the product more accessible and affordable for consumers. Therefore, using this approach, businesses utilize automation tools, software, machinery, and systems that automate repetitive tasks and minimize lead times.

2- Assembly or production lines

A specialized line to assemble part of the products in a standardized order, moving along a conveyor belt by machines or workers. In repetitive manufacturing, the companies are manufacturing highly similar products, which means they will be making hundreds of thousands of similar products on a weekly or monthly basis. Factories using this approach have large production or assembly lines with automation to speed up the repetitive process. That saves time, cuts resources, and minimizes lead times.

3- Master Data

Master data is an exhaustive data collection regarding the material, components, and production processes. Companies use inventory management software or other tools to keep all the data in one place to increase visibility.

In repetitive manufacturing, it’s important to have complete visibility into everything because a single shortage can interrupt the whole process.

On another side, it helps identify which material is no longer in use or needs to be replaced with something more higher quality for better quality control.

4- Schedule tables

Just like master data, companies practicing a repetitive approach follow master schedule tables with everything planned, organized, and aligned on a single platform. It is again done by using comprehensive inventory management tools or software that keep track of what material is being used in which products, how much of it has been used, and what’s remaining. They also help plan the next reorder, decide which material to eliminate, and determine which to upgrade. Using these tables, companies can easily identify which material is consistently being used and plan the next batch to meet the demand in advance.

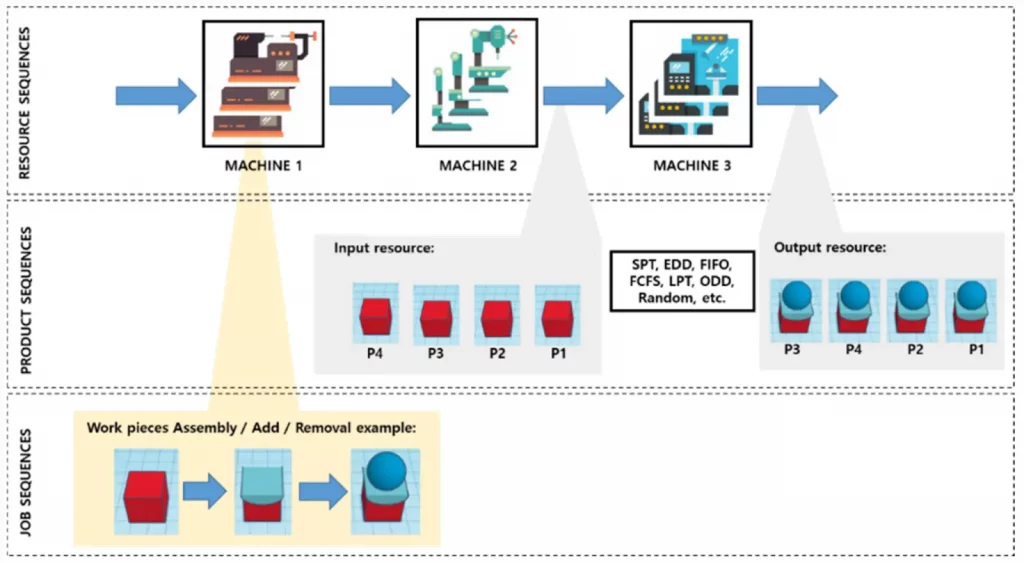

5- Sequencing

It’s another characteristic of repetitive manufacturing, where products or parts are arranged in an optimal order or sequence to improve the production process or tasks. For example, in factories, we see how production follows a specific sequence, with each step usually followed by the same next step to keep the process orderly and reduce disruptions. In repetitive manufacturing, there is a clear sequencing throughout the production process to ensure the products being made are standardized and of consistent quality.

6- Standardization

Another feature of repetitive manufacturing is maintaining the specified standard of the product. This means the input (material, component, or process) used must be standardized to produce the same output with minimal or no variations. When the process is standardized, it is easier to identify and eliminate any errors. Additionally, in the standardized practice, the company can always find areas for improvisation and improvement to ensure the highest possible quality.

7- Quality control

When you have complete visibility into each process and step, you can quickly spot errors or malfunctions. Therefore, by using standardized practices and software that ensure everything is in order, companies maintain quality control at every stage until the final product is out.

What is the difference between discrete and repetitive manufacturing?

One of the most common questions out there is:

“How is repetitive manufacturing different from discrete manufacturing?”

Let’s break it down:

In repetitive manufacturing, the products made are similar with identical specifications and produced in mass quantities.

While in discrete manufacturing, a company manufactures individual, distinct products. These are often made based on specific customer orders (customized) or in defined lots. One can think of it as project-based or order-based production, where each item or batch might have unique specifications, complex routings, and distinct bills of material (BOM).

In contrast to repetitive manufacturing, in discrete manufacturing, the different parts of the product that are being assembled to make a final product are usually made at different locations/sites across the country or world and then pulled together to make an end product.

| Feature | Repetitive | Discrete |

| Product Type | Standardized | Customized |

| Setup Time | Minimal | Frequent changeovers |

| Planning Style | Forecast-based | Order-based |

| Flexibility | Low | High |

| Examples | Car parts, smartphones | Furniture, custom machines |

Benefits of repetitive manufacturing

1- Cost effectiveness

When doing mass production, the cost per unit drops significantly. That makes repetitive manufacturing one of the most cost-effective approaches.

Let’s talk about some data.

- Manufacturing businesses can reduce operating costs by up to 20% by optimizing their processes.

- Automation can potentially reduce overall costs by 10% to 50%.

- Data fabric solutions using RM reduced operational costs by 18.7% in the first year, including 21% lower inventory costs and 22% lower quality control costs.

With the latest automation tools, equipment, and software, companies can accelerate the entire production process, which lowers costs throughout the entire process.

2- Simplified process

Just like the name suggests, repetitive processes are simpler than discrete ones. With repetitive processes, companies can easily use tools to automate tasks, and most of the equipment used is standardized, which makes it easier to learn and operate rather than learning to operate different equipment, software, and processes every few months.

3- Waste minimization

In RM, rather than increasing production frequency with different materials, a consistent standardize process is repeated every week. With complete visibility into the entire process, companies can implement practices to minimize waste and ensure proper management of materials, products, and components to prevent pollution caused by excess wastage.

4- Easy staff training

In RM, staff do not need weekly training to operate completely new equipment. Sometimes, upgraded versions of existing equipment or software do not require additional training, keeping the process simple and straightforward. In other manufacturing methods, where different products are produced and staff must learn to operate new tools and equipment, repetitive manufacturing becomes much easier.

5- Boosted productivity and efficiency

RM boosts production flow. Manufacturers using data fabric solutions have seen an average 27% reduction in production cycle times. Real-time data access can cut production planning time by 65%, and automated workflows can reduce process delays by 42%. Bottlenecks are identified 3.5 times faster with integrated data analysis. Overall, 76% of businesses use automation to standardize daily workflows, allowing teams to focus on more strategic activities. Automation also empowers small businesses to compete more effectively with larger companies, a sentiment shared by 88% of small business owners.

6- Reduced lead times

In RM, standardized practices reduce lead times. How? By improvising their production process, companies ensure they shorten their production cycle and, in turn, minimize lead time while maintaining the quality of goods.

Companies that consistently optimize their processes can reduce lead times by over 40%, with many achieving 25-30% reductions within 90 days through targeted efforts. The greatest potential for improvement usually comes from cutting non-value-added time, as materials typically spend 95% of their time waiting between operations, whereas actual production cycle time only makes up 10-20% of the total manufacturing lead time.

7- Improved quality control

Mass production ensures product uniformity, giving manufacturers greater control over quality. With continuous inspection, testing, and data analysis, you can identify and prevent defects early. That makes it easy to maintain quality.

8- Simplified planning & scheduling

The consistent nature of RM simplifies scheduling and makes it more flexible, allowing for adjustments with minimal user effort.

End note

Like every approach, repetitive manufacturing is not an ideal practice for all businesses. If you deal in products with consistent demand over months and years with little or no interventions, then it might be a great way to cut extra expenses. However, if you handle mostly custom products with changes made based on customer demand, then discrete manufacturing might be a better option for you. Again, if you want to streamline your entire production process, make sure to use inventory management tools that increase visibility into each step and prevent wastage or shortage.

FAQs

What is an example of repetitive manufacturing?

Automotive manufacturing is an example of repetitive production where cars move through the same assembly line repeatedly, maintaining consistent standards and quality.

What is the difference between discrete and repetitive manufacturing?

In repetitive manufacturing, the products made are similar with identical specifications and produced in mass quantities.

While in discrete manufacturing, a company manufactures individual, distinct products. These are often made based on specific customer orders (customized) or in defined lots.

What is an example of repetitive assembly?

Manufacturing automobiles on an assembly line. Automobiles are placed on a conveyor belt where parts are assembled in proper sequence. This process is repeated for every vehicle on the line.

What is the difference between repetitive and continuous manufacturing?

Both repetitive manufacturing and continuous manufacturing are forms of mass production, but they differ in raw material type, process flow, flexibility, and end-use industry.

Repetitive manufacturing uses discrete raw materials (like nuts, bolts, metal parts, etc.) to assemble standardized products over and over again, often on an assembly line. It’s commonly used in industries like automotive, electronics, or appliance manufacturing.

Continuous manufacturing, on the other hand, typically deals with raw materials in liquid, gas, or powder form (like chemicals, oil, or food ingredients). The process runs 24/7 with no interruptions and is used in industries like pharmaceuticals, oil refining, and food processing.